Centurion® Configurable Controller

The Centurion C5 Configurable Controller is the core of the Centurion control and monitoring system. The C5 Controller puts users in control with diagnostics that reduce troubleshooting, improve communication and enhance data management.

- Fully configurable control and monitoring system with applications for reciprocating/screw compressors and pump systems

- Expandable system to meet most three- or four-stage compressor applications

- User configurability with Windows-based software allows the operator to point and click to implement standard processes, and if authorized, configure the I/O points

- No programming experience required

- Local and remote communications, Modbus RTU via RS485/232/Ethernet

- USB 1.1 / 2.0 support for laptops without a serial port

- Upload/download capabilities for configurations and set points

- Shut-down history list (Last 20 events)

- Event history list (Last 32 events)

- Active alarm list

- 10 configurable maintenance timers

- Run hourmeter

- Support for no-flow totalization using lubricator pulses

- Short cycle start protection / starts per hour (electric motor)

- Eight control loops (ISA PID or Linear)

- Configuration templates provided for simple use

- Configurations stored in non-volatile flash memory

- Set points stored in non-volatile EEPROM memory

- Production Programmable, CS&S can modify to meet customer requirements without engineering support

- CAN capable, to support electronic engines

- One core module for Standard and Custom applications

- DIN Rail Mountable

- View EICS and Centurion systems on one M-View® Touch screen display

- Ability to upgrade your older Centurion LCD display to the M-View for higher resolution, less scrolling and brighter backlight

- Diagnostics that reduce troubleshooting

- World-class certifications and harmonized international standards

- Future-proof and backward compatible

- All non-incendive inputs

- Compressor Rod Load calculation, alarm and shutdown

FW Murphy Production Controls offers support for all our products. If you are unable to find the product that you need, please call us at 918-957-1000.

Primarily designed for engine/electric motor driven compressors, the Centurion is well suited for many control applications using standard configurations to save money and reduce training. Additionally, FW Murphy specializes in custom designing control packages to meet exact specifications for a variety of applications.

Continuously monitoring input signals, set points and command outputs to maintain proper operation, the Centurion C5 Controller will stop, shut down or control equipment to change conditions when an out-of-limits event occurs. The auto-start capabilities of the Centurion allow for start/stop based on parameters such as pressure set points or by digital signals.

The Centurion provides real-time data via communication ports to a connected display and any remote monitoring system through Ethernet and serial methods.

This Centurion consists of one C5 main I/O module, one M-View display module and the option of adding MX4-R2 and MX5-R2 expansion I/O modules. The Centurion is designed for use only within a weatherproof enclosure. No special cables required.

C5 Series Main I/O Module

- Operating temperature: -40° to 185° F (-40° to 85° C)

- Power input: 30 W max 10-30 VDC

- Configuration: PC-based Centurion Configuration software

- Application firmware:

- Standard offers a user-configurable experience

- Centurion Custom option offers highly customized applications. Integrate with Rockwell Automation Processors as I/O module to write IEC 61131-3 logic (ladder logic, structured text, function block diagram).

- All I/O options individually software selectable: No jumpers required

- Clock: Battery backed internal real-time clock, approximately 10 years unpowered service life

- 12 Analog inputs*:

- 0-24 mA or 0-5 VDC, 15-bit hardware

- 4 resistive potentiometer measurement

- 32 Digital inputs*:

- NO or NC (active high/active low) intrinsically safe

- Optically isolated DC digital inputs (active high/active low) with LED indicators

- Polarity sense / wire fault detection on normally closed systems

- Approved for use with general purpose switches in hazardous areas

- Eight temperature inputs*:

- J or K type thermocouples (ungrounded)

- 3-wire 100Ω Pt RTD temperature inputs***

- Open, short DC-, short DC+ wire fault detection

- Cold junction compensation

- One magnetic pickup input/AC run signal:

- 30 to 10 kHz, 4.5 VAC rms min, 120 VAC rms max

- 10 digital outputs:

- LED indicators:

- 4 relay outputs, form C, dry contacts

- 4 FET outputs (source)

- 2 FET outputs (sink)

- LED indicators:

- Four analog outputs:

- 4-20 mA, 16-bit hardware

- 11 Communication ports:

- Two SERIAL RS232:

- Protocol: Modbus RTU (server)

- Two SERIAL RS485:

- Protocol: Modbus RTU (server)

- One USB: host type A (data log access, firmware updates)

- One USB: interface type B (configuration / firmware updates)

- Two CAN:

- One proprietary for FW Murphy hardware

- One reserved for J1939 Engine ECU

- Two Ethernet 10/100 (DLR):

- Protocol: Modbus TCP/IP (server)

- EtherNet/IP (CIP)

- One WiFi: Optional C5-1 only

- Two SERIAL RS232:

- Third-party approvals:

- Class I, Div 2, Grps A, B, C, D Haz. Loc. T4

- Class I, Zone 2, AEx ec [ic] nC IIC T4 Gc, Ex ec [ic] nC IIC T4 Gc X

- ATEX Zone 2

- II 3G Ex ec [ic] nC IIC T4 Gc

- DEMKO 18 ATEX 1926X

- -40°C < Tamb < +85°C

- IECEx Zone 2

- Ex ec [ic] nC IIC T4 Gc

- IECEx UL 18.0072X

- -40°C < Tamb < +85°C

MX4-R2 Expansion I/O Module

- Operating Temperature: -40° to 185° F (-40° to 85° C)

- Power input: 14.1 W max 10-30 VDC

- Configuration: PC-based Centurion Configuration software

- 18† thermocouple inputs*: J or K type thermocouples (ungrounded)

- 9† 3-wire 100Ω Pt RTD temperature inputs*,***

-

- Open, short DC-, short DC+ wire fault detection

- Cold junction compensation

- One magnetic pickup input* / AC Run Signal: 4.5 VAC – 120 VAC, 30 Hz – 10 kHz

- Third-party approvals:

- Class I, Div 2, Grps A, B, C, D Haz. Loc. T4

- Class I, Zone 2, AEx ec [ic] IIC T4 Gc, Ex ec [ic] IIC T4 Gc X

- ATEX Zone 2

- II 3G Ex ec [ic] IIC T4 Gc

- DEMKO 18 ATEX 1926X

- -40°C < Tamb < +85°C

- IECEx Zone 2

- Ex ec [ic] IIC T4 Gc

- IECEx UL 18.0072X

- -40°C < Tamb < +85°C

MX5-R2 Expansion I/O Module

- Operating temperature: -40° to 185° F (-40° to 85° C)

- Power input: 16.5 W max 10-30 VDC

- Configuration: PC-based Centurion Configuration software

- 24++Digital inputs*:

- NO or NC (active high/active low) intrinsically safe

- Optically isolated DC digital inputs (active high/active low) with LED indicators

- Polarity sense / wire fault detection on normally closed systems

- Approved for use with general purpose switches in hazardous areas

- 10 analog inputs*: 0-24 mA or 0-5 VDC, 15 bit hardware

- 6 std. config./ 16++* digital outputs: FET (sink)

- 4 analog outputs: 4-20 mA, 16 bit hardware

- 1 magnetic pickup input* /AC Run Signal: 4.5 VAC -120 VAC, 30 Hz to 10 kHz

- Third-party approvals:

- Class I, Div 2, Grps A, B, C, D Haz. Loc. T4

- Class I, Zone 2, AEx ec [ic] IIC T4 Gc, Ex ec [ic] IIC T4 Gc X

- ATEX Zone 2

- II 3G Ex ec [ic] IIC T4 Gc

- DEMKO 18 ATEX 1926X

- -40°C < Tamb < +85°C

- IECEx Zone 2

- Ex ec [ic] IIC T4 Gc X

- IECEx UL 18.0072X

- -40°C < Tamb < +85°C

* Non-incendive (digital inputs, analog inputs and temperature inputs are intrinsically safe and non-incendive).

++ Applies only to Centurion™ Custom and Rockwell Automation® Processor configurations.

*** RTD=Resistive Temperature Device, American RTD Standard, TCR 0.00392, units Ohms / Ohm / deg. between 0-100 C.

† When configured for an RTD channel, two consecutive odd/even T/C channels are consumed.

M-VIEW® Monochrome Display MV-5-C

- Operating temperature: -40° to 185° F (-40° to 85° C)

- Power input: 11 W max 10-30 VDC

- Screen: 320 x 240 pixels, LCD display with backlight

- User interface: 12-key keypad set point entry, alarm acknowledgment, start, stop, reset, etc.

- Communications:

- RS232-1/RS485-1 (Modbus RTU client)

- RS485-2 (Modbus RTU server)

- 1 USB interface type B (firmware updates)

- 1 USB host type A (reserved)

- CAN x 2

- 1 proprietary for FW Murphy hardware

- 1 reserved for J1939 engine ECU

- Customizable process screens (up to nine):

- Line by line

- Gage

- Control loop

- Generic register

- Built-in screens (examples):

- Digital input status and polarity

- Digital input status and polarity

- Digital output status

- Temperature input status/fault

- Fault snapshot (mirror of line by line)

- Alarm log

- Third-party approvals:

-

- Class I, Div 2, Grps A, B, C, D Haz. Loc. T4

- Class I, Zone 2, AEx ec ic [ic] IIC T4 Gc, Ex ec ic [ic] IIC T4 Gc X

- ATEX Zone 2

- II 3G Ex ec ic [ic] IIC T4 Gc

- DEMKO 18 ATEX 1926X

- -40°C < Tamb < +85°C

- IECEx Zone 2

- Ex ec ic [ic] IIC T4 Gc

- IECEx UL 18.0072X

- -40°C < Tamb < +85°C

-

M-VIEW® Touch Displays MV-7T and MV-12T

- Operating temperature: -4° to 140° F (-20° to 60° C)

- Power input:

- MV-7T, 15 W max 10-30 VDC (36 W max with modules)

- MV-12T, 23 W max 10-30 VDC (57 W max with modules)

- Screen (sunlight readable):

- MV-7T, 800×480 pixels, 7” widescreen, brightness 1000 cd/m2

- MV-12T, 1280×800 pixels, 12” widescreen, brightness 1600 cd/m2

- User interface: resistive analog touchscreen

- Communication interface:

- 2x RS232

- 1x RS485

- 2x USB host type A (file transfer, datalogging, USB device)

- 1x USB server (program/firmware updates)

- 2 Ethernet 10/100 Base TX (RJ45)

- Communication protocols:

- EtherNet/IP (CIP)

- Modbus TCP/IP

- Modbus RTU standard

- 300 plus available, web server

- Third-party approvals:

- CE Approved

- EN 61326-1 Immunity to Industrial Locations Emission CISPR 11 Class A

- IEC/EN 61010-1

- RoHS compliant

- ATEX Approved

- II 3 G Ex ic nA IIC T4 Gc

- II 3 D Ex tc IIIC T135°C Dc

- DEMKO 14 ATEX 1387X

- EN 60079-0, -11, -15, -31

- IECEx Approved

- Ex ic nA IIC T4 Gc

- Ex tc IIIC T135°C Dc

- IECEx UL 15.0035X

- IEC 60079-0, -11, -15, -31

- UL Approved

- cULus Listed for Ordinary Location: File #E302106

- UL 61010-1, -2-201

- cULus Listed for Hazardous Location: File #E317425

- Class I, Division 2, Groups A, B, C and D

- Class II, Division 2, Groups F and G

- Class III, Division 2 ANSI/ISA 12.12.01, C22.2 No. 213-M1987, 157-92

- cULus Listed for Ordinary Location: File #E302106

- IP66 enclosure rating (face only)

- Type 4X outdoor enclosure rating (face only)

- ABS type approval for shipboard applications

- CE Approved

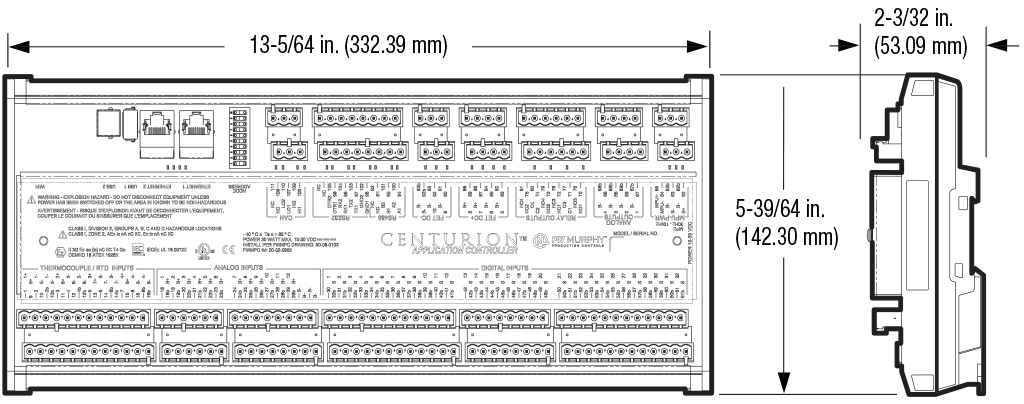

C5 Series I/O Module Controller

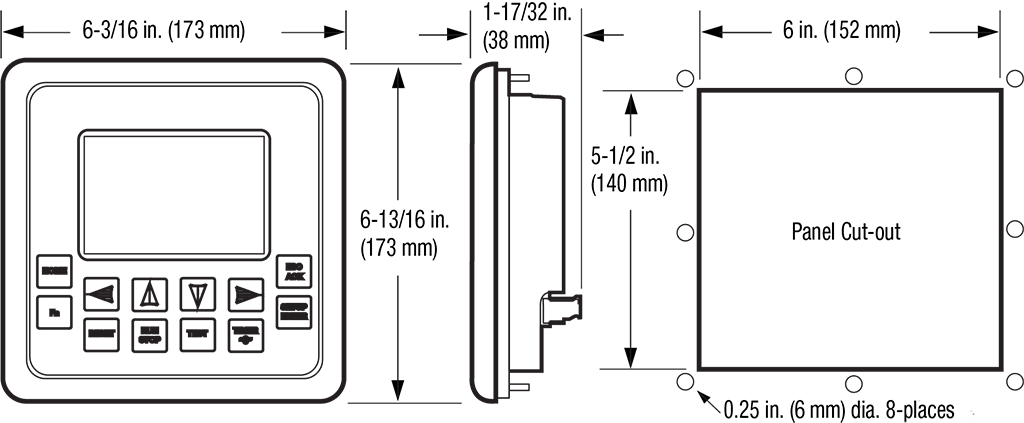

MV-5 Display

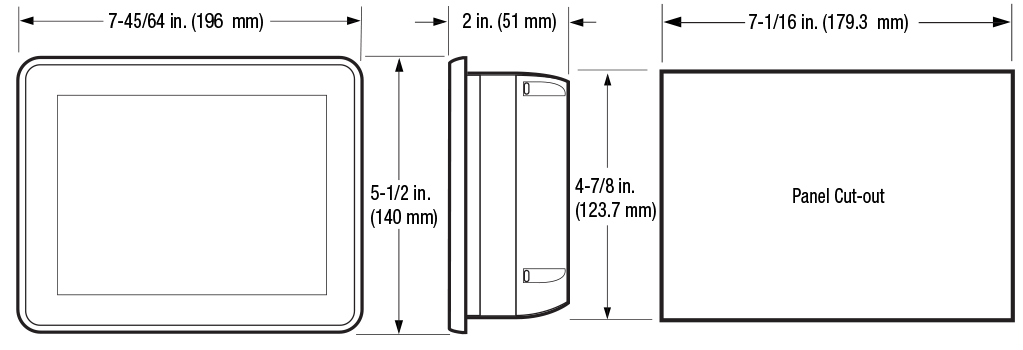

MV-7T Display

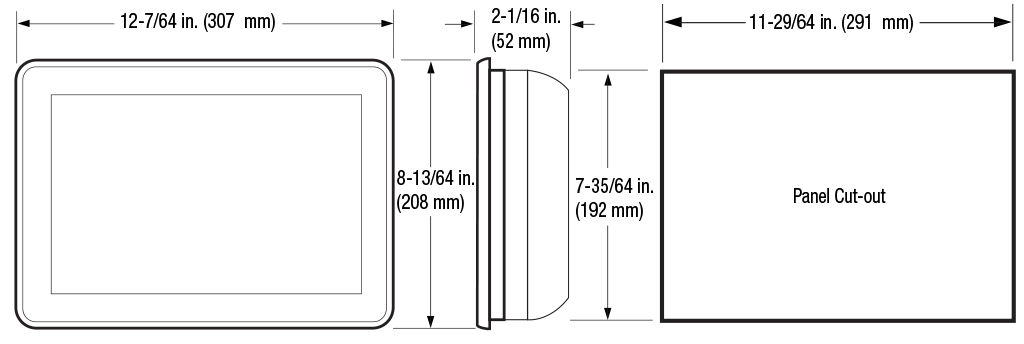

MV-12T Display

For more information about this product, you can download the related literature here:

Centurion® C5 Series

Centurion C5 Configurable Controller Bulletin (1815230; revision date: 02/2024)

Centurion C5 Custom Controller Bulletin (1915295: revision date: 02/2024)

Installation Manual C5 (00020963; revision date: 03/2025)

Quick Start Guide C5 (00021033; revision date: 12/2020)

Operations Manual C5 and MV-5-C (00021031; revision date: 08/2022)

Operations Manual C5 and MV-7T or MV-10T (00021032; revision date: 08/2022)

Important USB Information (1815242; revision date: 06/2018)

Centurion C5-ASC Modbus Application Guide Map (2215418; revision date: 11/2023)

Centurion C5 Series Modbus Application Guide Map (1815243; revision date: 11/2023)

M-VIEW®

M-VIEW 7″ Touch Display Installation Manual (LP1083; revision date: 08/2020)

M-VIEW 10″ Touch Display Installation Manual (LP1082; revision date: 08/2020)

M-VIEW 12″ Touch Display Installation Manual (LP1095; revision date: 08/2020)

M-VIEW RTU Controller with Module Installation Manual (LP1080; revision date: 11/2018)

M-VIEW CCP Module Installation Manual (LP1081; revision date: 11/2018)

M-VIEW J1939 Module Installation Manual (LP1084; revision date: 11/2018)

M-VIEW Touch Adapter Panels For G3 Units Cutout (2115398; revision date: 06/2021)

Brochure

Brochure C5 (1815246; revision date: 07/2024)

Flier Centurion Rockwell Automation (2315442; revision date: 08/2023)