Leading natural gas compression services provider Exterran anticipates performance and emissions benefits with the Engine Integrated Control System (EICS®) from FW Murphy.

As a global market leader in full service natural gas compression, Exterran offers the latest technology and proven industry standards in a wide range of high-speed reciprocating and rotary screw compressor packages. Houston-based Exterran was presented with a significant new challenge in 2009. The Environmental Protection Agency (EPA) proposed a regulation that would require about 8,500 units in the company’s North American fleet of natural gas engine-powered compressors to include emissions control equipment. After extensive research into potential retrofit solutions, Exterran selected the Murphy Engine Integrated Control System (EICS) to meet emissions-compliance and performance-optimization needs for the impacted compression equipment.

One Solution, Multiple Benefits

Designed and tested for specific spark-ignited, natural gas-fueled engines, the EICS integrates key components for engine optimization – including ignition system, air/fuel control, speed governing, interface and diagnostics, sensors, harnessing, catalyst and the engine control module – into one complete package.

“Due to the material impact of the proposed EPA regulation, we turned to FW Murphy Production Controls. In our opinion other product offerings were insufficient for keeping equipment in continuous compliance under changing operating conditions,” says Mike Wasson, Exterran director of North American fleet services. While emissions compliance was a driving force behind the decision, the potential for increased engine efficiency and optimized equipment performance was equally influential. Since piloting the first EICS-equipped compressor in September 2010, Exterran and its customers have realized emissions compliance and performance benefits – and the packager expects additional advantages as the equipment accumulates run time.

“We’ve seen a lot of things in our EICS-equipped engine packages that excites us about the future in terms of engine management and emissions controls,” says Ray Purtzer, Exterran vice president of North American fleet services.

Initial Performance Results Promising

Exterran incorporated the EICS into packages featuring four specific continuous-rated engine models:

Arrow VRG 330 (68 bhp)

Caterpillar® G3304NA (95 bhp)

Caterpillar G3306NA (145 bhp)

Caterpillar G3306TA (203 bhp)

(since this case study, EICS has expanded to include the Caterpillar 3406 and the Cummins KTA19.)

By combining key components into one package, the EICS saved Exterran cost and labor associated with the installation and calibration of separate products. “It’s probably a 15 to 20 percent savings in labor hours versus if we had to install each component individually,” says James Harrison, Exterran technical field services manager.

The EICS integrates the three main components for engine optimization – ignition system, air/fuel ratio control and speed governing – into a single engine control module (ECM) to ensure optimum performance across all scenarios without the need for manual field adjustments.

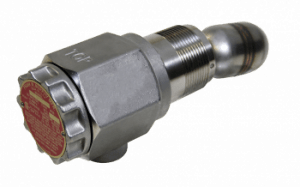

EICS air/fuel control is achieved through the combination of an innovative Murphy direct electronic pressure regulator (D-EPR) valve with a wide-band oxygen sensor. The D-EPR valve accommodates wide variations in fuel composition and speed/load range, maintaining efficiency with load-following technology for even the toughest gas lift applications. The speed governing component of the EICS consists of an integrated throttle used to manage the flow of the air/fuel mixture to the engine, which maximizes engine performance and helps maintain emissions.

Upon deployment, the EICS had an immediate impact on engine efficiency and operational performance of Exterran equipment. “The EICS definitely improves fuel economy, which is very important to us and our customers,” Harrison says. “The EICS has the ability to change the ignition timing and speed of the engine on demand, which results in increased fuel economy estimated around 2 to 3 percent in most applications.”

Besides increased fuel efficiency, Exterran anticipates that the EICS will deliver improved uptime when facing load swings and changes in natural gas well flow conditions that would typically shut down an engine. “I see us being able to address a portion of the unscheduled callouts related to low suction pressure, which equates to more uptime for our customers,” Harrison says.

When developing the EICS, FW Murphy Production Controls leveraged its existing ignition system, which features a capacitive discharge ignition system and uses Smart Coil technology to measure and display kilovolt (kV) readings required to fire the spark plug in each cylinder. By measuring the kV readings, the EICS provides comprehensive engine diagnostics and prognostics.

When operational issues arise, the EICS streamlines troubleshooting by monitoring all integrated system components. If an out-of-limit event occurs, the EICS pinpoints the original malfunction event even when multiple alarms are triggered as a result of the original event.The advanced diagnostics eliminate the need for operators to test and troubleshoot each component separately.

“The EICS makes the engine run better, and when the engine runs better, we have less downtime and less repair costs involved,” Harrison says. “The diagnostics allow us to quickly troubleshoot issues, keeping the compression services online for our customer.

“We think there’s a lot of opportunity for better performance. I also think we could see a lengthened life cycle between engine overhauls, which would equate to bottom-line dollars.”

Early Impact on Emissions EncouragingFor gas compression operators facing emissions regulations, the EICS is available in an emissions version, which integrates the catalyst into the package. Exterran opted for the emissions version to achieve compliance with a spectrum of local, state, federal and customer-mandated standards.

Incorporation of the EICS reduces the resources required by allowing automation of emissions control. Because FW Murphy Production Controls conducted extensive dynamometer testing up front, operators can be certain that their site will pass required emissions testing.Exterran expects the EICS to be much more dependable than previous emissions solutions, which included a standard air/fuel controller, traditional stepper fuel control valve and catalyst. While Wasson acknowledges that these solutions can be effective in controlling emissions, he says obtaining emissions limits with existing controls equipment requires an extensive amount of manual intervention, programming and labor hours.

“The problem with programming is that it takes considerable time and experience,” Wasson says. “With the EICS, (FW Murphy Production Controls) has done that work for us by mapping out the engine’s performance on a dynamometer and programming it into the software of the system.”

“If the machine remains as consistent as it has in field testing, we can significantly reduce the amount of effort required to maintain compliance even with the most stringent emission standards,” says Kyle Jantzen, Exterran manager of air programs. “That translates to less labor and less setup time, so we have great hope for reducing our cost. And with this system, there is no tweaking necessary to maintain emissions compliance.”

Jantzen expects ease and speed in testing equipment that has historically proven difficult in emissions testing. “One of our pilot packages has shown we can cut testing time on difficult equipment by at least 30 percent,” he says. “Another perceived benefit would be a reduction in emissions control-related nuisance calls.”

Jantzen expresses optimism that the EICS-equipped products not only meet current emissions regulations in a safe range but will achieve future requirements. “We feel like the EICS is by far the most comprehensive long-term solution out there,” Jantzen says. “We have confidence that our equipment and maintenance practices are going to keep the equipment in compliance around the clock, now and in the future.”

Ultimately, Exterran expects the EICS to strengthen its leadership position in the market by revitalizing older assets with a retrofit solution providing increased engine efficiency, optimized equipment performance and emissions compliance.

“We think the EICS is another tool in our belt that will allow us to continue to offer superior solutions,” Purtzer says. “This system will revitalize some aging portions of our compressor fleet of equipment. And our customers’ perception is that Exterran is willing to get on the cutting edge of technology and lead the industry.”

Download this Case Study as a PDF

Recent Comments