Pressure Transmitters

The PXT-K Series pressure transmitters are state-of-the-art instruments that can be used in applications such as compressors, engines, process control, liquid level and pumps.

- Piezoresistive pressure transmitter

- Used with compressors, engines, process control, liquid level and pumps

- 4-20 mA output signal

- Corrosion resistant construction

- High stability

FW Murphy Production Controls offers support for all our products. If you are unable to find the product that you need, please call us at 918-957-1000.

The PXT-K Series pressure transmitters are state-of-the-art instruments providing 4-20 mA output. Each piezoresistive pressure transmitter contains a transducer comprised of a piezoresistive silicon chip mounted on a glass-metal feed-through header welded into a stainless steel housing and filled with silicone oil. The very thin laser-welded stainless steel isolation-diaphragm completes the front side. Media pressure is transferred from the stainless steel isolation-diaphragm via the oil inside the cell to the silicon measuring chip. This construction, combined with the advanced internal signal conditioning circuitry, results in a rugged instrument with extremely small temperature error and class-leading EMI/RFI resistance.

The enclosure and all wetted parts are made of 316L stainless steel.

Operating Range

- Operating Pressure Range:

- See How to Order under the PXT-K Series Model Number Matrix in the FW Murphy bulletin

- Operating Temperature:

- -22° to 176° F (-30° to 80° C)

- Compensated Temp Range:

- -20° to 160° F (-29° to 71° C)

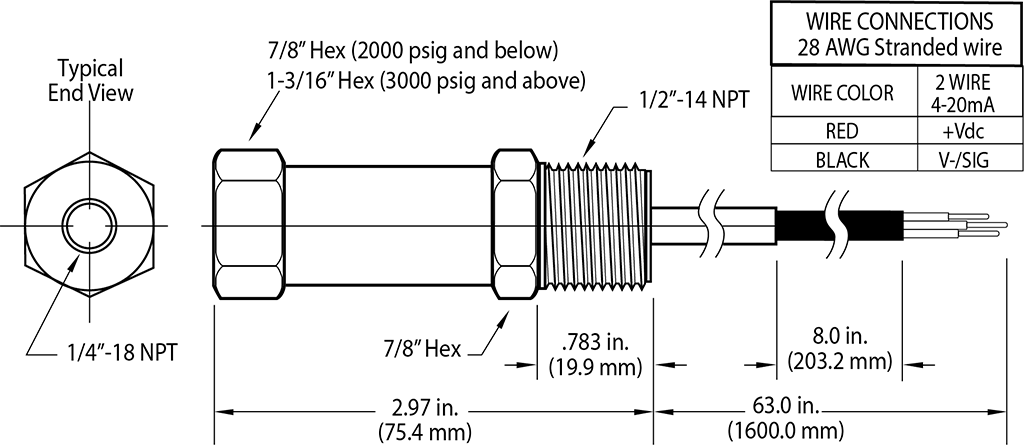

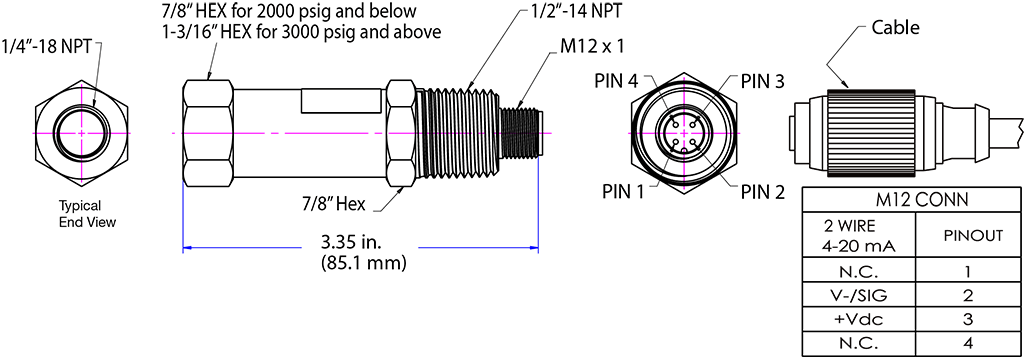

- Process Connection: 1/4 in. -18 NPT female with 7/8 in. or 1-3/16 in. hex nut

- Electrical Connection:

- PXT-K: 1/2 in. NPT male conduit connection with 60 in. long cable, vented

- PXT-KM: M12 connector

- Enclosure Rating: IP65

- Body: 316L stainless steel

- Wetted Parts: 316L stainless steel

- Environmental Effect (Humidity): No effect for 0-95%, non-condensing

- Mounting: Transmitter can be installed in any axis. Transmitter position has negligible effect on performance as long as it is perpendicular to the flow being monitored.

- Shock Resistance: 800g per IEC 60068-2-27 (Mechanical Shock)

- Vibration Resistance: 20G per IEC 60068-2-6 (Vibration under resonance)

- Wiring Protection: Protected against reverse polarity and short circuit, 48 VDC Maximum

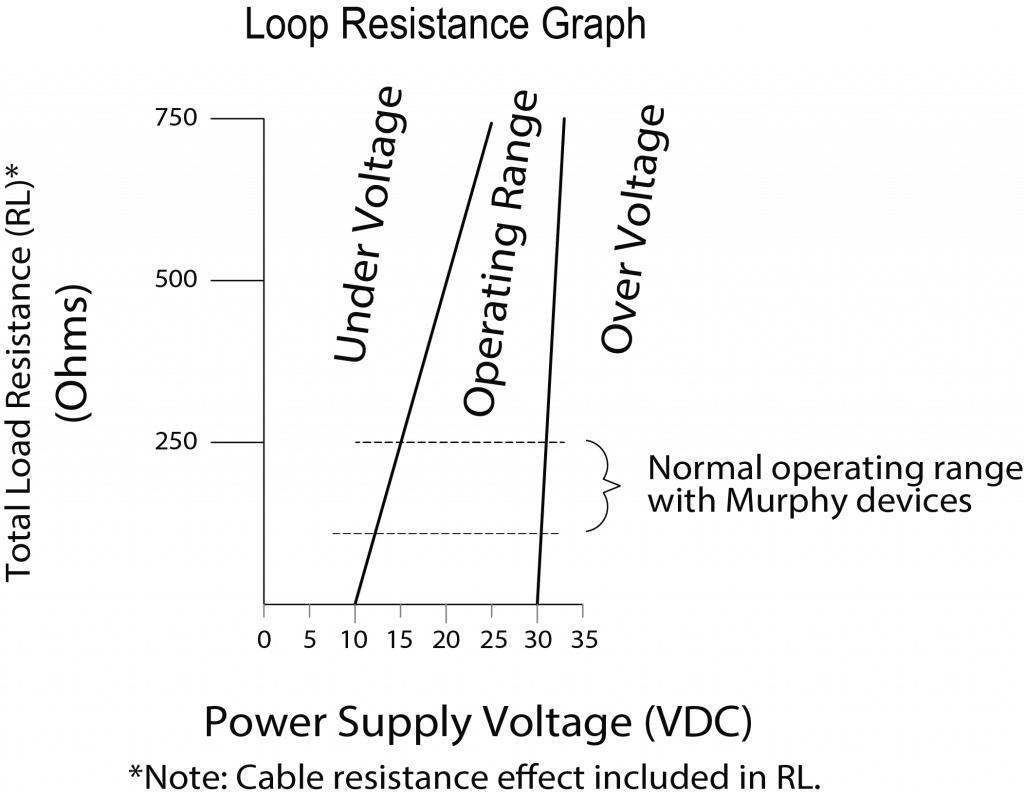

- Supply Voltage: 10 – 30 VDC (Typically 24 VDC)

- Transmitter Output: 4-20mA, two wire configurations with load characteristics

- Insulation: Greater than 10MΩ @ 300 VDC

- Electromagnetic Compatibility (EMC): Standards; EN 61000-6-2:2005, EN 61000-6-3:2007, EN 61326-2-3:2006

- Voltage Surge/Spike Protection: Protection against a 600-volt spike per IEC 60-2

- Shipping Weight: 6.5 ounces

Applicable Standards

- CSA (c/us):

- Class I / II / III, Div 1, Groups A-F T4

- Class I / II / III, Div 2, Groups A-D,F,G T4

- ATEX:

- IBExU 10 ATEX 1124 X

- II 1G Ex ia IIC T6-T4

- II 3G Ex nA IIC T6

- Canadian Registration Number: OF15236.2 (all provinces and territories)

PXT-K, 2000 and 3000 psig

PXT-KM, 2000 and 3000 psig

Operating Range

For more information about this product, you can download the related literature here:

Sales Bulletin (1211009; revision date: 12/2024)

Installation Instructions (00-02-0840; revision date: 12/2024)

PXT Series Cross Reference Chart

PXT-K and PXT Series Cabling Identification (2215412; revision date: 02/2022)